Abs Plastic Injection Molding Price

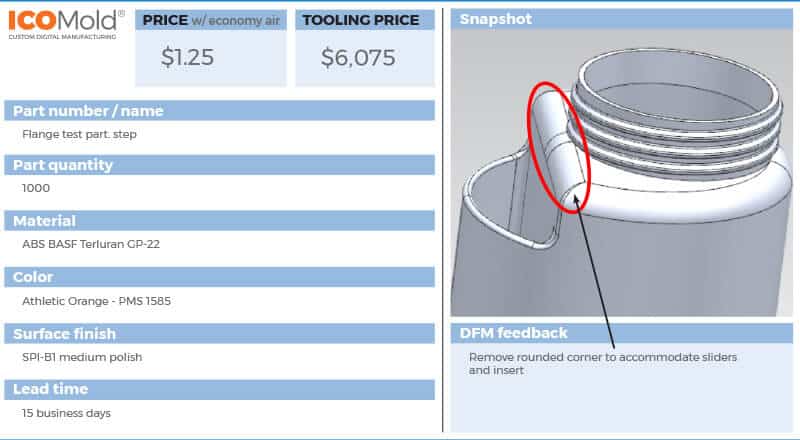

But we know injection molding price estimates are critical to any successful project.

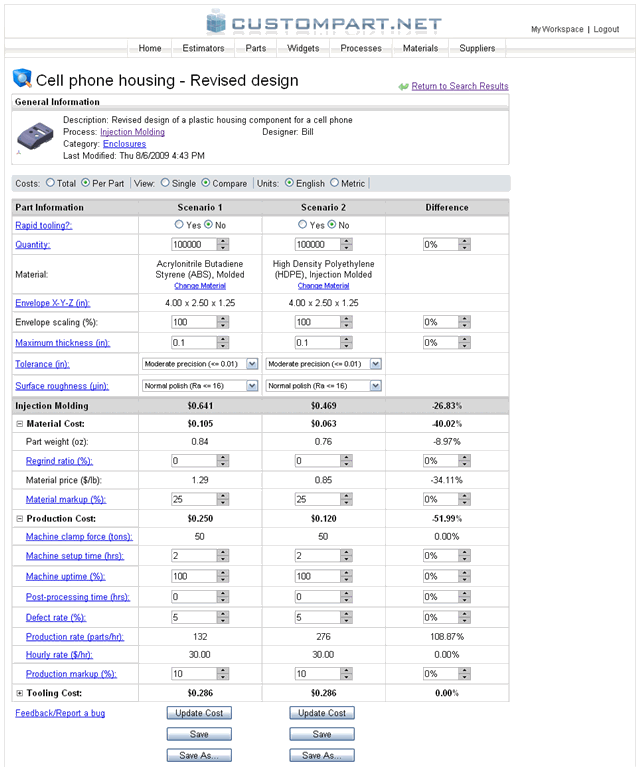

Abs plastic injection molding price. Get in touch with us today at 86 0 769 3366 9997. Invite colleagues or customers to directly view your estimate. Abs plastic is a copolymer of acrylonitrile butadiene and styrene and generally possess medium strength and performance at medium cost. Build your own complete process plan and generate detailed cost estimates.

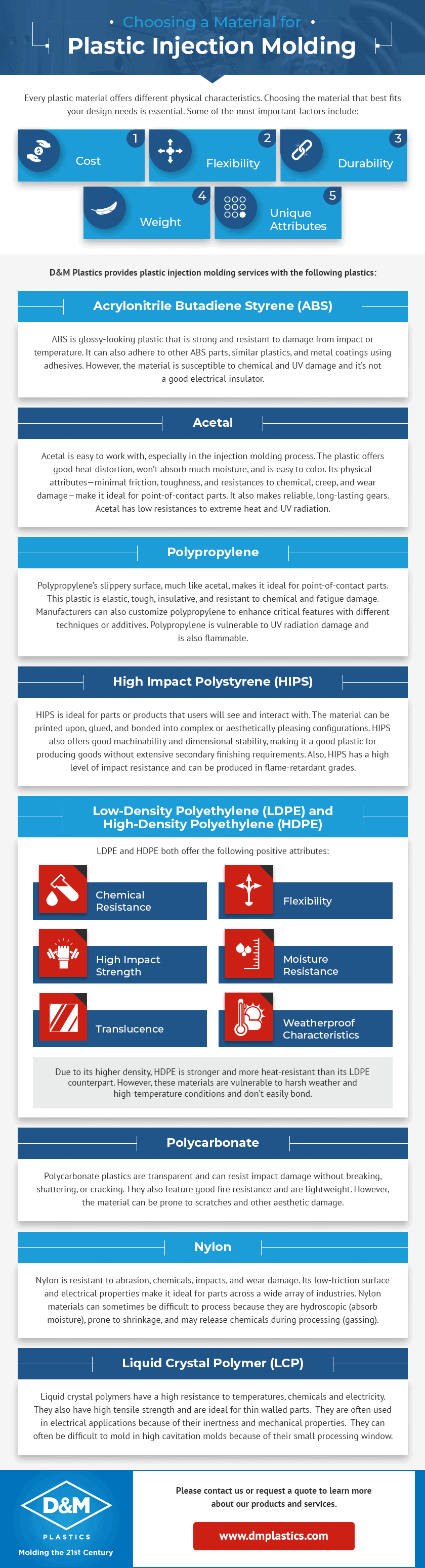

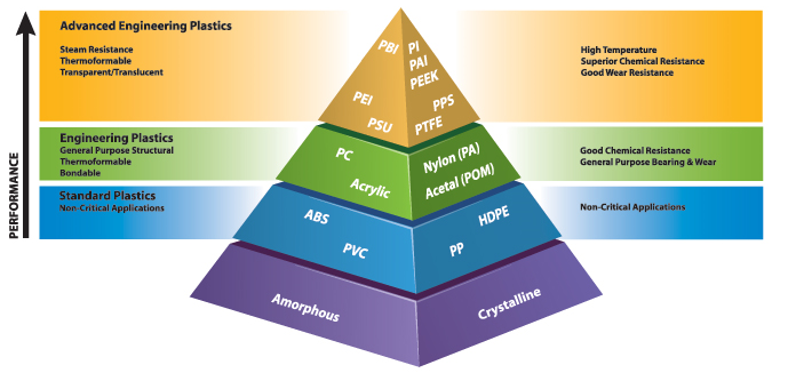

Prices of these materials are very crucial information to be tracked off regularly. Thermoplastic as opposed to thermoset refers to the way the material responds to heat. Acrylonitrile butadiene styrene abs is an opaque thermoplastic and amorphous polymer. The best way to figure out how much you can save with injection molding services over other manufacturing methods is to compute the cost per part.

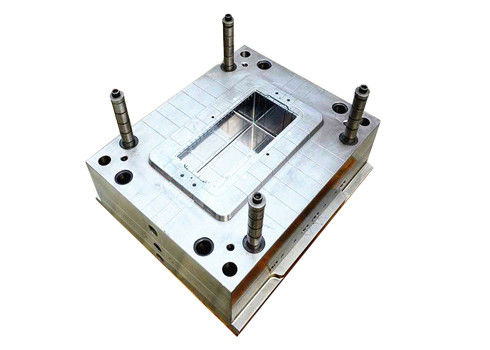

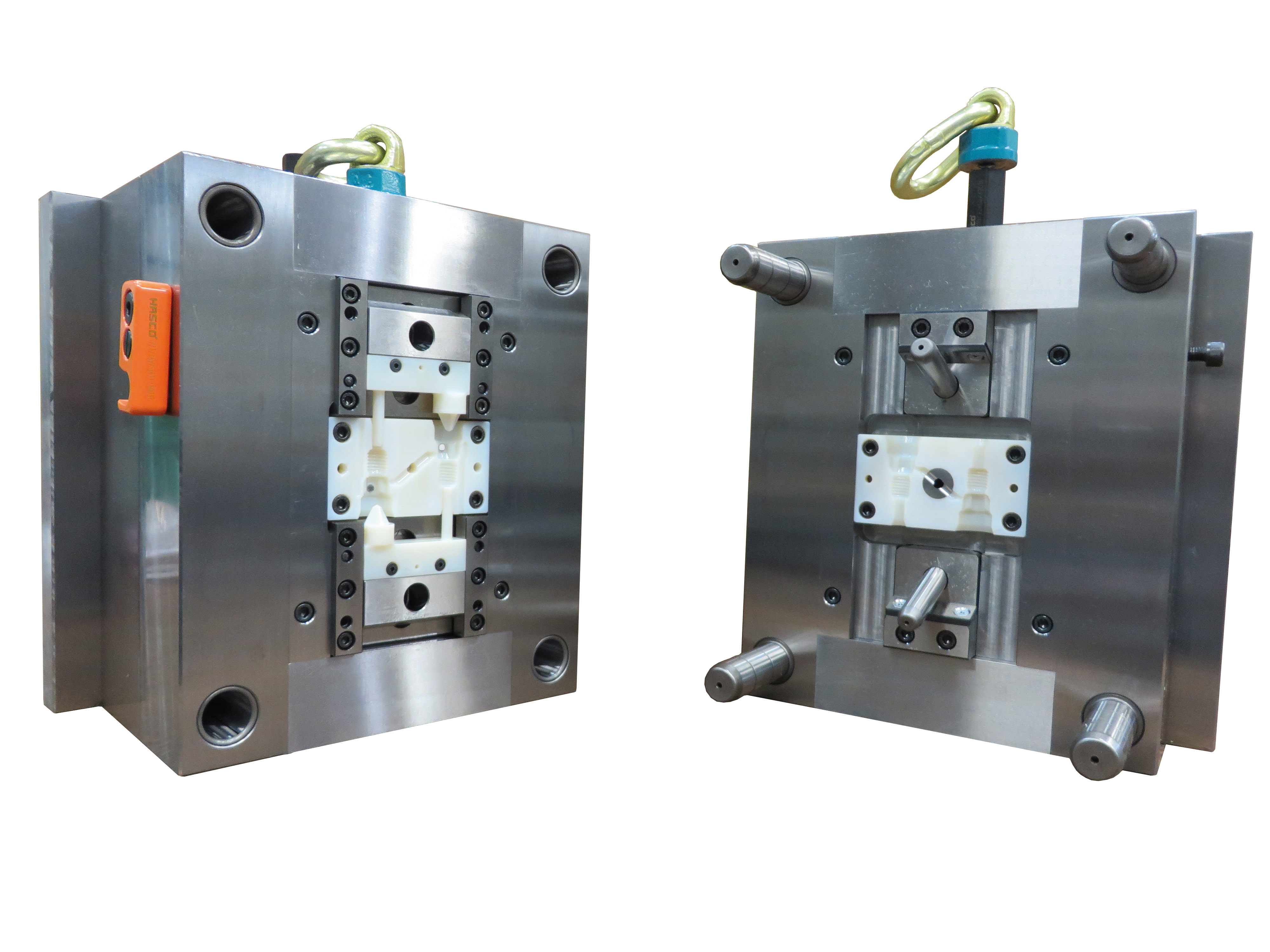

Injection molding machines are typically referred to by the tonnage of the clamping force they provide. Abs acrylonitrile butadiene styrene is a thermoplastic resin commonly used for injection molding applications. As a full service plastic injection molding company that manufactures molds from conception to completion pricing for each job we fulfill can vary dramatically. The hourly rate is proportional to the size of the injection moulding machine being used so it is important to understand how the part design affects machine selection.

40 00 peek pellets 50 lbs. Plastic injection molding price guide. Polypropylene pp 20gf is a stronger resin then typical pp and an alternative for abs for injection molding applications. We are top abs injection molding plastic mold company offers you abs injection moulding custom abs plastic molding at affordable prices.

Different types or grades of resins such as hdpe ldpe pet pp san abs pmma and many others are available in the market. Thermoplastics become liquid i e. Have a glass transition at a certain temperature 221 degrees fahrenheit in the case of abs plastic. Last updated on april 23 2020.

Although there are certain factors that can drive the cost of injection molding up or down if you begin with the right formula to calculate the cost per part you may be able to make adjustments that will lower that.