A Bend In Sheet Metal Is Than The Surrounding Area

It can wreak havoc in the press brake department and cause cracking on the outside surface of the bend.

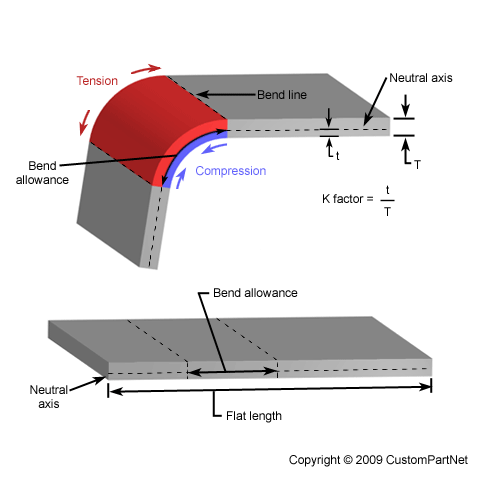

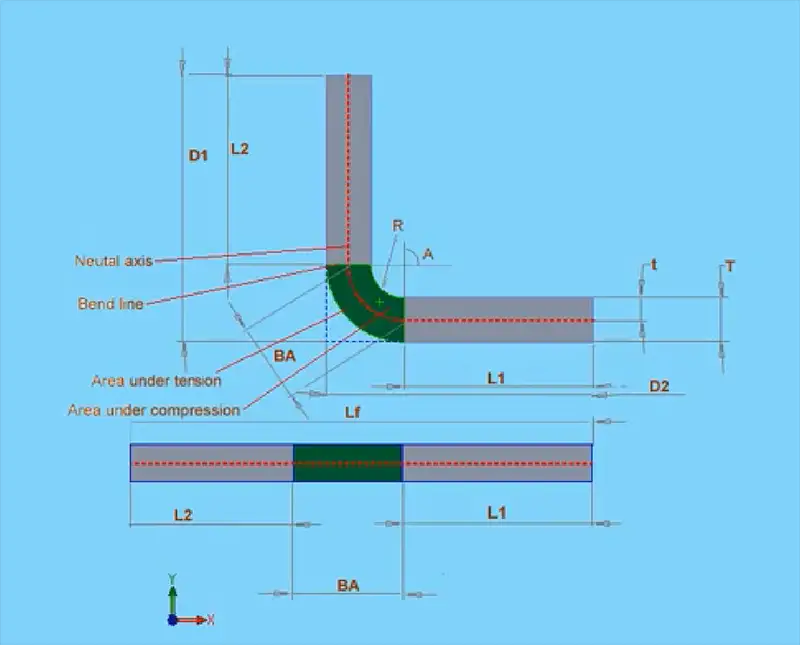

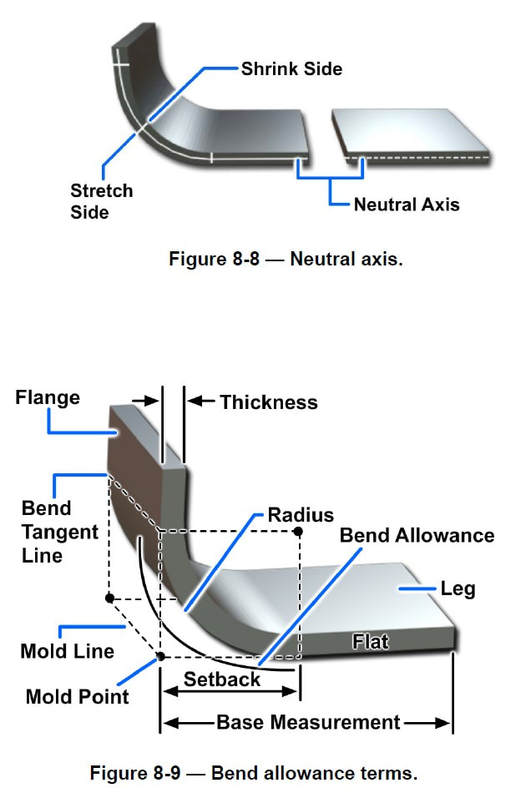

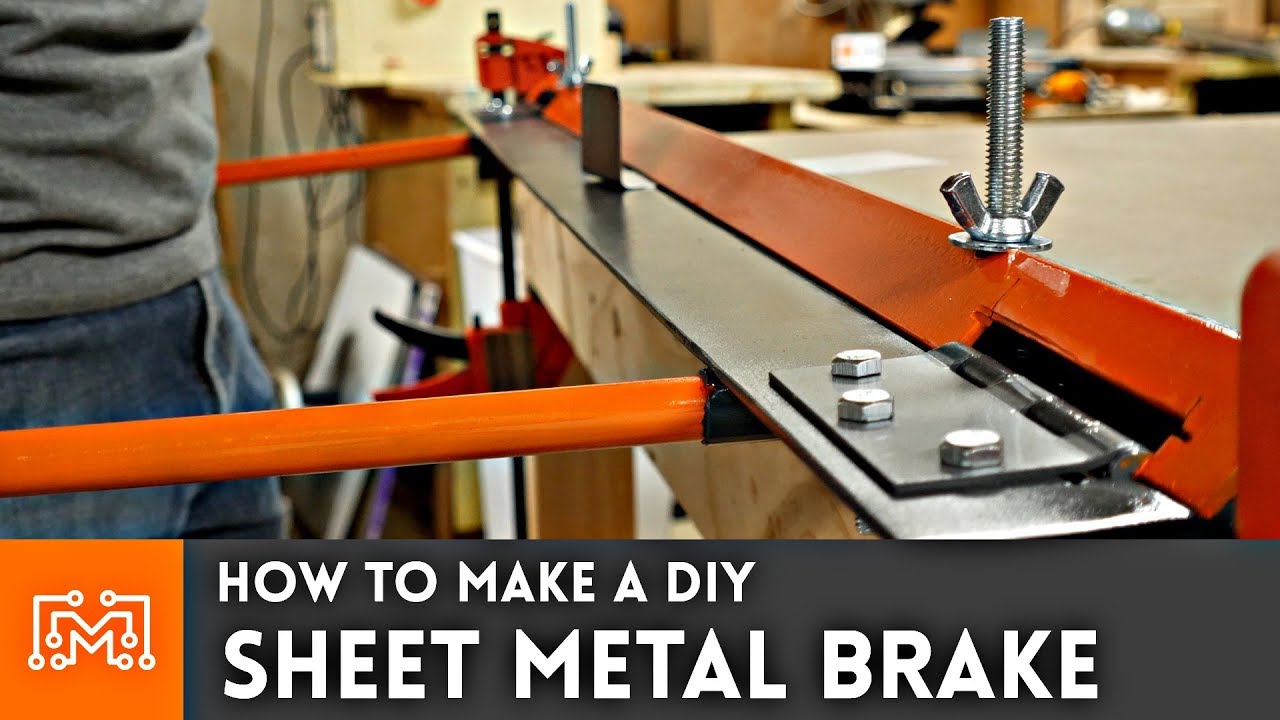

A bend in sheet metal is than the surrounding area. To define the bend region and reduce the force required to bend a part out of sheet metal down to something you can handle without a brake press slots can be cut at the bending line to selectively. Minimum sheet metal flange bend length 3 x sheet thickness bend radius. Bend steel works fabrication has a complete inventory of aluminum and steel in stock for your immediate needs. The inside bend radius should be equal to the thickness of the material that you re forming.

For example if you are using 14 gauge stainless steel a240 tp304 2b and opt for a minimum bend of 275 then your cutouts must be no closer than 275 to a bend. In case we don t have your preferred material in stock we can order it right away or point you in the right direction. It shall be equal to three times of sheet thickness plus bend radius. If you re bending 0 020 thick material use a 0 020 radius.

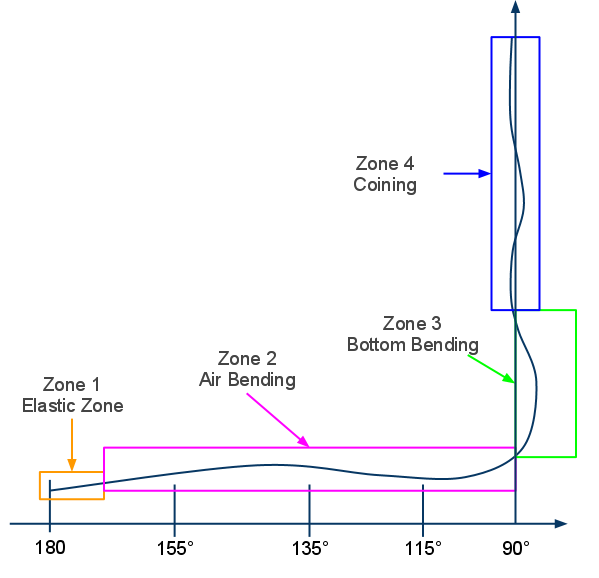

In other words if you re bending 1 8 sheet use a tool with a 1 8 radius to form the inside of the bend. Determine your minimum bend by measuring the distance from your closest feature i e. A bend made too sharp develops plastic deformity from the excessive stress caused by the bending. Pressure permanently bend the outer part of the sheet but the inner part does not reach the elastic limit.

However angles greater than 90 degrees will require more complex equipment capable of some horizontal force delivery. Edge bending is another very common sheet metal process and is performed with a wiping die. You only have to insert interior angle flange lengths k factor inside radius and material thickness. Choose a bend radius that matches your minimum bend.

If you have any questions or want to discuss your design contact us. Cells on the right will output the desired values. Therefore the inner side tends to recover its original shape. Our materials range from tubing bend oregon sheet metal bundles of rebar and many more.

Edge bending gives a good mechanical advantage when forming a bend. A common problem in both the sheet metal and plate industries involves parts designed with an inside bend radius much tighter than necessary. By using the minimum bend dimension value for your minimum closeness of cutout to a bend you will ensure you run into no issues i often get asked by customers how far a cutout.