A 60 Kg Air Compressor Is Mounted On The Floor

Use neoprene vibration isolators under compressors air conditioning equipment pumps machine tools transformers and more.

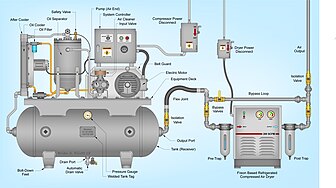

A 60 kg air compressor is mounted on the floor. Carrier experts provide sustainable solutions integrating energy efficient products building controls and energy services for commercial customers. How do you mount secure your vertical air compressor. Alternative to anchor bolts are the explosive bolts that you can buy at the hardware store it uses a charge like a 22 shell to fire a bolt into concrete. Figure 1 shows a common example of a vibration source a large reciprocating air conditioning compressor weighing 20 000 pounds mounted on a roof.

Powermate vibration isolator can also help prevent wear and tear to the compressor and air hoses caused by the intense vibration of the unit during use. Required tools for this project have the necessary tools for this diy project lined up before you start you ll save time and frustration. The pads help reduce vibration noise and help protect your compressor so it lasts longer. As a few folks mentioned the correct way is to bolt the compressor to the floor using isolation pads.

For use with stationary units. Vibration pads provide support for stationary air compressors. Refer to your air compressor manual for specific installation requirements. Unlike gas and water lines air compression lines don t require perfect joints so don t worry if they leak a tiny bit.

Spring floor mount vibration isolators feature steel springs that help reduce vibration transmissions as performance improves with larger deflections. Mount the large stationary compressor to the floor with powermate vibration isolators for minimized reverberation. This of coarse would raise the compressor above the surrounding floor and keep any water runoff from pooling around the feet. G ratings meet horizontal requirement of most seismic zones.

1 vibration isolator pad 4 in. Reduce noise and extend the life of your air compressor with these heavy duty vibration pads. Annoying noise levels at multiples of the compressor rotational frequency predominantly 60 and 120 hz were measured in the rooms directly below the compressor. Anchoring a 60 gallon air compressor an alternative would be to form up a new pad on top of the existing floor.

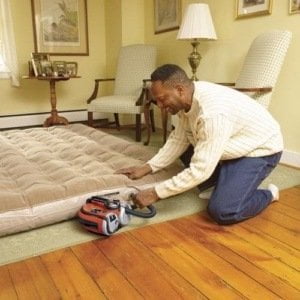

Certain tools demand higher psi than others and an air compressor must exceed the maximum rating from a given set of tools to cover the owner s working needs. The pressure at which air is delivered from a compressor measured in terms of psi is another critical factor in the ability of an air compressor to power pneumatic tools properly.